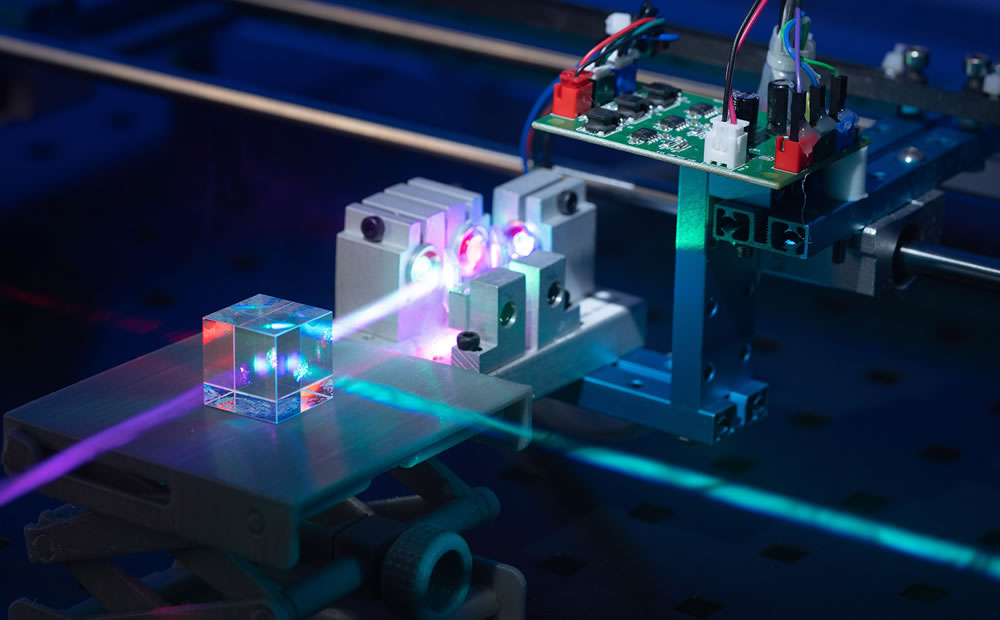

Using deep learning technology to screen for various defects on the glass surface. Calculate and analyze the type and location of each defect, and upload the data to the cloud. High-speed inspection reduces labor costs.

Particle Size refers to the indentation radius caused by a single conductive ball.

Particle Count represents the total number of particles within a single inspection pin frame.

Particle Distribution refers to the ratio between the distribution range of all particles within a single inspection pin frame and the length of the pin frame in the Y direction.

The In-Vehicle Small Panel AOI (Automated Optical Inspection) is a self-developed equipment system by our company, designed specifically for high-precision defect detection in LCD screens. The product boasts user-friendly interfaces, high accuracy, flexible configurations, and efficient and stable operation.

Utilizing proprietary visual algorithms, it can accurately detect various defects such as panel edge chips, breaks, liquid crystal defects, uneven acid etching, bumps, dents, and surface scratches. The inspection process is highly efficient, with a false positive rate stabilized below 10% and a missed detection rate kept within 0.5%.

Display all detected defect thumbnails for the current sample on the C-side/T-side, showing the current number, total inspected quantity, OK quantity, NG quantity, number of scratches, number of glass fragments, number of residual adhesives, and yield rate.

Accurate Detection: Precisely measures the thickness of the product.

Parameter Setting: Allows for the setting of relevant parameters for thickness detection based on production process requirements.

Data Interaction: Enables data exchange with the MES system.

The Vision-based Scanning Series is a range of devices developed by integrating cameras onto various barcodes, character codes, QR codes, and other tooling fixtures. These devices are designed to be compatible with different sizes of glass and can undergo tooling modifications to accommodate for variations in the position of the codes on the glass. By automating the scanning process, they replace manual scanning and significantly enhance production efficiency.

lt.jin@xae.com.cn

No. 2, Yu'an Road, Wuhu Area, China (Anhui) Pilot Free Trade Zone

No. 2, Yu'an Road, Wuhu Area, China (Anhui) Pilot Free Trade Zone

lt.jin@xae.com.cn

Copyright © Wuhu Xin'an Intelligent Equipment Co., Ltd. All Rights Reserved. Sitemap

ICP备案号:皖ICP备2024054541号-1